How to Choose the Perfect Kiln for Enameling

As an experienced enameling enthusiast, I’ve learned that the key to creating stunning and durable enamel pieces lies in selecting the right kiln. The kiln plays a crucial role in the enameling process, as it provides the necessary heat to fuse the glass-like enamel to the metal surface. In this comprehensive guide, I’ll share my insights on how to choose the perfect kiln for your enameling projects.

Choosing the right kiln can be a daunting task, especially for beginners. There are various factors to consider, such as the size of your projects, the temperature requirements, and the overall functionality of the kiln. In this article, I’ll walk you through the essential considerations to help you make an informed decision and ensure that your enameling endeavors are a resounding success.

Do you need a kiln for enameling?

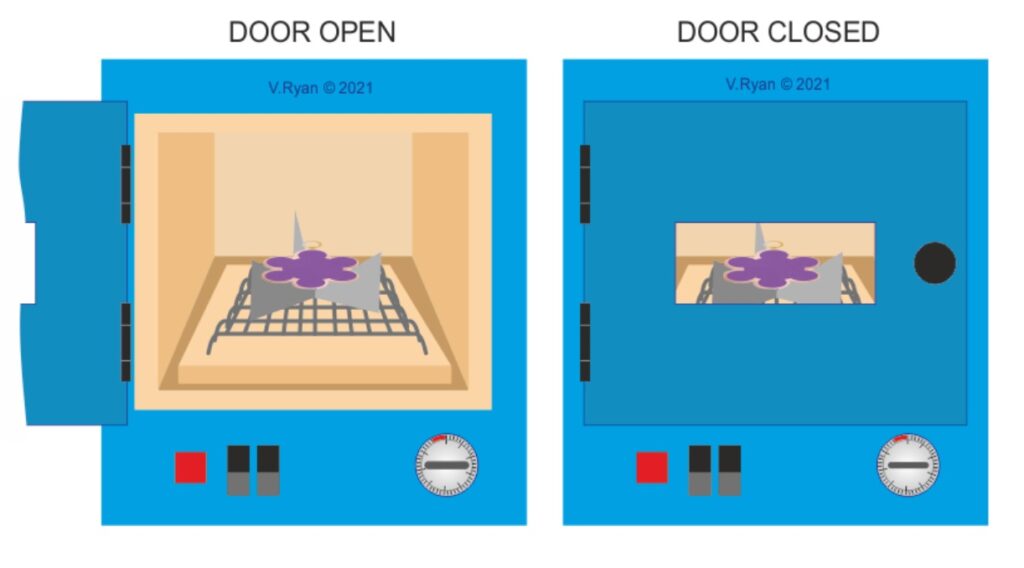

Absolutely! A kiln is an essential tool for enameling. Enameling is the process of fusing powdered glass to a metal surface, typically copper or silver, through the application of intense heat. Without a kiln, it would be virtually impossible to achieve the high temperatures necessary for the enamel to melt and bond with the metal.

The kiln provides a controlled and consistent heat environment, allowing the enamel to melt and flow evenly over the metal surface. This fusion creates a durable, glossy, and vibrant finish that is the hallmark of beautiful enamel work.

What temperature is the kiln for enameling?

The temperature required for enameling can vary depending on the specific type of enamel you are using, but generally, the temperature range for enameling is between 1400°F (760°C) to 1600°F (870°C). This high heat is necessary to melt the enamel powder and allow it to flow and adhere to the metal substrate.

It’s important to note that different types of enamel may have slightly different temperature requirements. For example, low-fire enamels may melt at lower temperatures, around 1400°F (760°C), while high-fire enamels may require temperatures up to 1600°F (870°C) or even higher.

When choosing a kiln for enameling, make sure it can reach and maintain the necessary temperature range for the specific enamel you plan to use. Consulting the manufacturer’s recommendations or seeking advice from experienced enamelers can help you determine the ideal temperature requirements for your projects.

How do you enamel without a kiln?

While a kiln is an essential tool for enameling, there are alternative methods that can be used, albeit with more limitations. One such method is the use of a handheld torch or a small butane-powered kiln. These tools can provide the necessary heat to melt the enamel, but they typically have a smaller working area and may not offer the same level of temperature control and consistency as a traditional kiln.

Another option is to use a microwave oven to enamel small pieces. This technique, known as “microwave enameling,” involves placing the metal piece with the enamel powder in a microwave-safe container and heating it in short bursts. However, this method can be more unpredictable, and the results may not be as consistent as those achieved with a dedicated enameling kiln.

It’s important to note that while these alternative methods can be used for enameling, they may not provide the same level of quality and durability as a properly sized and temperature-controlled kiln. For the best results and the most consistent enamel finishes, I highly recommend investing in a dedicated enameling kiln.

What temperature do most enamels melt?

The melting temperature of enamels can vary depending on the specific type of enamel and its composition. However, as a general guideline, most enamels melt within the range of 1400°F (760°C) to 1600°F (870°C).

This temperature range is necessary to ensure that the enamel powder fully melts and flows evenly over the metal surface, creating a smooth and uniform finish. If the temperature is too low, the enamel may not fully melt, resulting in an uneven or dull appearance. Conversely, if the temperature is too high, the enamel may become overly fluid, leading to unexpected results or even damage to the metal substrate.

It’s important to carefully follow the manufacturer’s recommendations for the specific enamel you are using, as some enamels may have slightly different melting temperature requirements. Consulting with experienced enamelers or referring to industry resources can also help you determine the optimal temperature range for your projects.

Can I use my oven instead of a kiln for enameling?

While it is possible to use a standard household oven for enameling, I would not recommend it as a long-term solution. Ovens are simply not designed to reach and maintain the high temperatures required for enameling, which typically range from 1400°F (760°C) to 1600°F (870°C).

Trying to enamel in a standard oven can lead to several issues:

- Temperature Limitations: Most household ovens have a maximum temperature of around 550°F (290°C), which is well below the necessary range for enameling. This means that the enamel may not fully melt and fuse with the metal, resulting in an uneven or incomplete finish.

- Temperature Fluctuations: Household ovens often have significant temperature fluctuations, which can affect the consistency and quality of the enamel finish. This can lead to uneven melting, bubbling, or other undesirable effects.

- Safety Concerns: Enameling requires extremely high temperatures that can pose a serious fire hazard in a standard oven. The intense heat can also damage the oven’s internal components over time.

While it may be possible to enamel small pieces in a household oven, this approach is not recommended for consistent, high-quality results. For the best and most reliable enameling outcomes, I strongly advise investing in a dedicated enameling kiln that can reach and maintain the necessary temperature range.If you’re ready to take your enameling skills to the next level, consider exploring our selection of high-quality enameling kilns. Our team of experts can help you find the perfect kiln to suit your needs and budget, ensuring that your enamel creations are nothing short of extraordinary. Contact us today to learn more!