Enameling is a beautiful and versatile technique used to create stunning jewelry and decorative objects. It involves applying a glass powder, known as enamel, to a metal surface and then firing it in a kiln. The enamel melts and fuses with the metal, creating a durable and vibrant finish.

Using a kiln is essential for enameling, as it provides the high temperatures needed to melt and cure the enamel. However, choosing the right kiln and understanding the enameling process can be overwhelming for beginners.

In this guide I will do my best to provide you with everything you need to know about using a kiln for enameling and jewelry making, from selecting the right equipment to mastering the techniques.

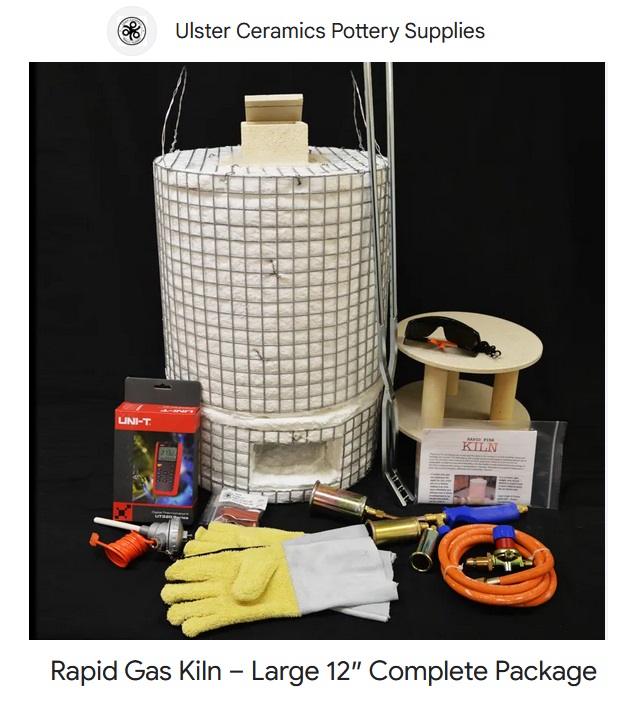

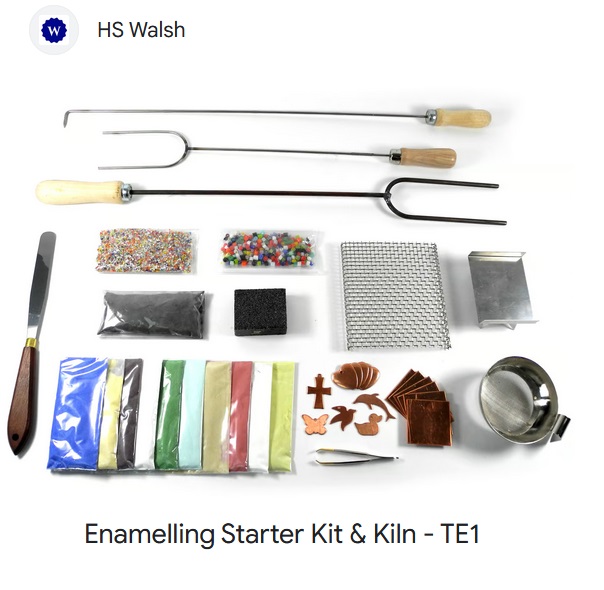

Choosing the Right Kiln or firing kit

The first step in enameling is to select a suitable kiln. The type of kiln you choose will depend on your needs, budget, and the size of your projects.

Here are some of the most common types of kilns and kits used for enameling:

- Electric Kilns – these are the most popular choice for home enamelers due to their convenience and ease of use. They are available in a wide range of sizes and temperatures, making them suitable for both small and large projects.

- Gas Kilns – gas kilns offer faster heating times and higher temperatures than electric kilns, making them ideal for larger projects or industrial applications. However, they require more maintenance and can be more difficult to operate.

- Torch firing – while not kilns per se, torches are used for smaller enameling projects and are often preferred by many jewelry makers. They involve using a torch to heat the metal and enamel, allowing for more precise control over the firing process.

When choosing a kiln, consider the following factors:

- Temperature Range – the kiln should be able to reach temperatures of at least 1,500°F (815°C) to melt and cure most types of enamel.

- Size – the size of the kiln should be appropriate for your projects. If you plan to enamel large pieces, you will need a larger kiln.

- Features – look for kilns with features such as automatic temperature control, digital displays, and safety alarms.

- Budget – kilns can vary widely in price, so it’s important to set a budget before you start shopping.

Preparing Your Workspace

Before you start enameling, it’s important to set up a safe and organized workspace.

Here are some tips for preparing your workspace:

- Choose a well-ventilated area – enameling can produce fumes, so it’s important to work in a well-ventilated space.

- Protect your surfaces – cover your work surfaces with heat-resistant materials to protect them from damage.

- Gather your supplies – gather all of your enameling supplies, including enamel, metal blanks, and tools.

Basic Enameling Techniques

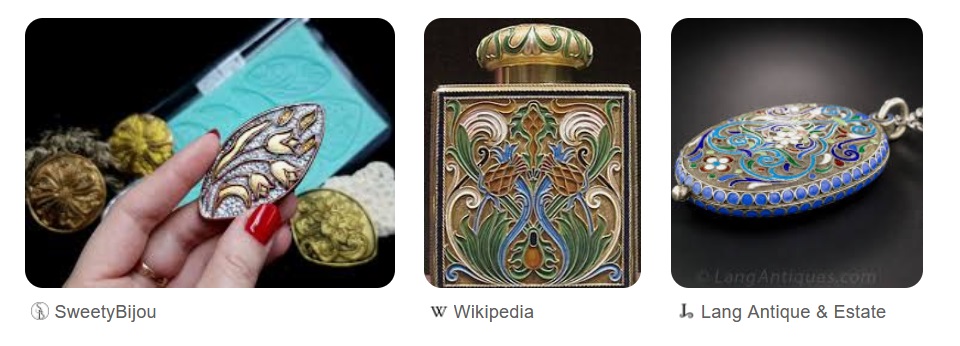

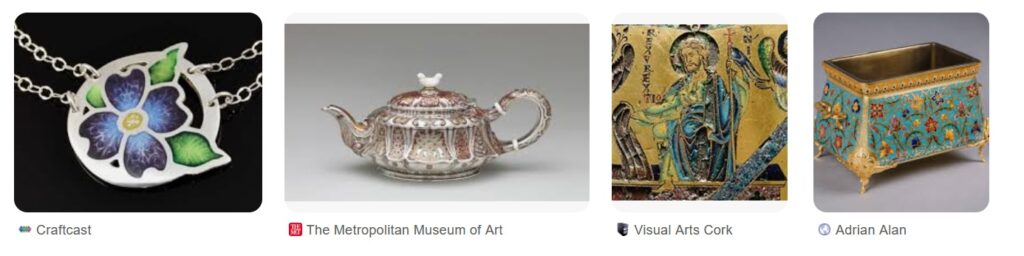

There are several basic enameling techniques that you can use to create beautiful jewelry and decorative objects. Here are some of the most common techniques:

- Cloisonné – this technique involves creating intricate designs using metal wires or strips. The design is then filled with enamel and fired in a kiln.

- Champlevé – this technique involves carving a design into a metal surface and then filling the cavities with enamel.

- Enamel Painting – this technique involves applying enamel to a metal surface using a brush or other tool.

- Fusing – this technique involves placing multiple layers of enamel on a metal surface and then firing it in a kiln. The enamel layers will fuse together to create a unique and textured effect.

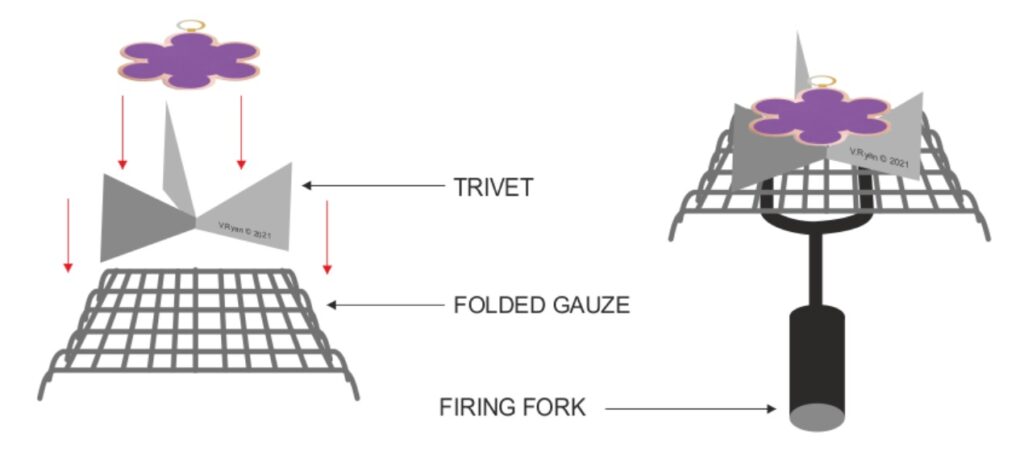

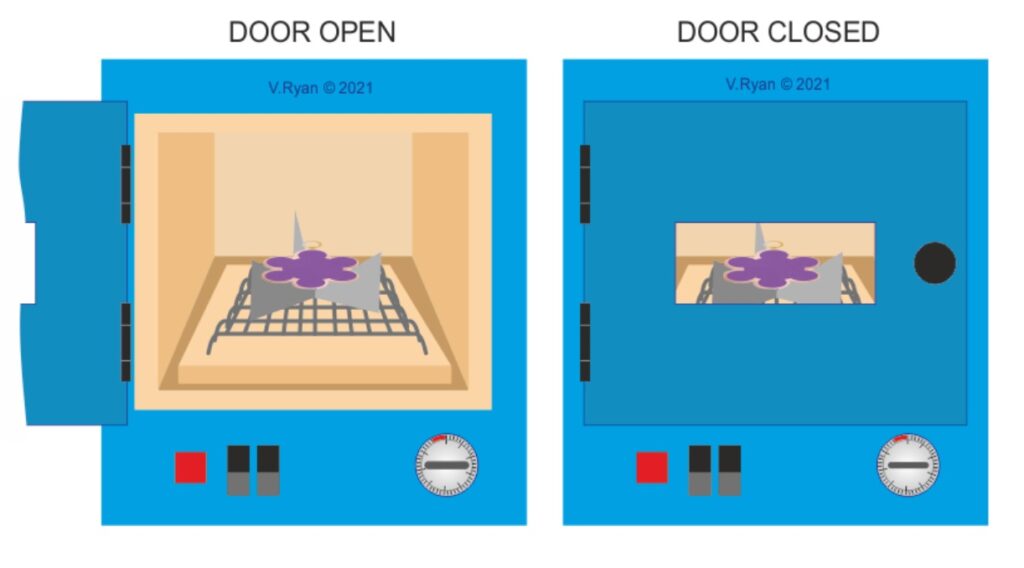

Firing Your Enamel

Firing your enamel in the kiln is a critical step in the enameling process. Here are some tips for firing your enamel:

- Follow the manufacturer’s instructions – always follow the manufacturer’s instructions for firing your enamel. This will help you ensure that your enamel cures properly and does not crack or chip.

- Start with a low temperature – begin firing your enamel at a low temperature and gradually increase the temperature over time. This will help prevent the enamel from cracking.

- Maintain a consistent temperature – it’s important to maintain a consistent temperature throughout the firing process. Avoid sudden temperature fluctuations, as this can cause the enamel to crack.

- Cool the kiln slowly – after firing your enamel, allow the kiln to cool slowly. This will help prevent the enamel from cracking.

Troubleshooting Common Enameling Problems

Enameling can be a challenging process, and it’s not uncommon to encounter problems. Here are some common enameling problems and their solutions:

- Cracked Enamel – cracked enamel can be caused by sudden temperature changes, overfiring, or using the wrong type of enamel. To prevent cracked enamel, follow the manufacturer’s instructions carefully and avoid sudden temperature fluctuations.

- Blistered Enamel – blistered enamel can be caused by trapped moisture or impurities in the enamel. To prevent blistering, make sure your enamel is dry before firing and use high-quality enamel.

- Uneven Enamel – uneven enamel can be caused by improper application or uneven heating. To create a smooth and even finish, apply the enamel evenly and ensure that the kiln heats evenly.

Advanced Enameling Techniques

Once you have mastered the basic enameling techniques, you can explore more advanced techniques. Here are a few examples:

- Kiln-fired Glass – you can use a kiln to fuse glass to metal, creating stunning jewelry and decorative objects.

- Dichroic Glass – dichroic glass is a type of glass that changes color depending on the angle of light. You can use dichroic glass to create unique and eye-catching enamel pieces.

- Gold Foil Enameling – gold foil enameling involves applying gold foil to a metal surface before applying the enamel. This creates a beautiful and luxurious finish.

Safety Tips for Enameling

Enameling can be a safe hobby, but it’s important to follow some basic safety precautions. Here are a few tips:

- Wear protective gear – always wear protective gloves, eye protection, and a mask when working with enamel and kilns.

- Avoid touching hot surfaces – never touch the kiln or the metal pieces while they are hot.

- Store chemicals safely – store all chemicals, such as enamel and solvents, in a safe and secure location.

- Follow safety instructions – always follow the safety instructions provided with your kiln and enameling supplies.

Enameling is a rewarding and creative technique, that allows you to create beautiful and unique jewelry and decorative objects. I hope that with the tips and techniques outlined in this article, you can use a kiln effectively and create stunning enamel pieces.